Properties and Top Uses of 6061 Aluminium Alloy

Aluminum in pure form has fixed properties like strength, melting point, and durability. However, now there are hybrid alloys available in the market that contain pure aluminum and other metallic elements. These alloys are stronger, durable, and flexible than pure metals – to use for a specific purpose. One such hybrid compound is 6061 Aluminum alloy.

Read on to learn about its preparation, components, properties, and top uses.

Preparation And Components of 6061

There are two categories of aluminum hybrid alloys:

Casting Alloys: These are those you can shape by casting in the sand or pouring into molds.

Wrought Alloys: These require rolling, forging, or extruding by hand to attain the desired shape.

Some wrought alloys are heat-treated via various processes to enhance their toughness and strength. The 6061 aluminum alloy is one of them. It is formerly known as “Alloy 61s” and was first produced in 1935. Its main components are magnesium, silicon, aluminum, chromium, and side elements are zinc, copper, titanium, and iron. The final result is a lightweight, medium to high strength, and economical material. The presence of chromium makes this alloy highly corrosion resistant.

Properties

The main properties of 6061 aluminum alloy include:

- Structural Durability and Hardness:

Alloying aluminum with other metals makes it almost as tough as steel. That’s why this alloy is known for its firmness and durability. - Excellence Surface Finish:

Despite the mixture of various metals, this alloy offers an excellent surface finish in any shape and size.

- Superior Corrosion Resistance:

As said earlier, the chromium present in the alloy makes it super corrosion resistant even if you use it underwater or in a high humid atmosphere.

- Easiness in Welding and Joining:

It is difficult to weld most aluminum alloys because of their poor conductivity and complex chemical composition. However, 6061 aluminum alloy is an exception. And if this material loses some strength, one can restore their sturdiness by re-heat treatment. - Machinability:

For those who are not aware of the meaning of this term, it is – how easily you can cut(machined) a metal. This property allows cutting the metal into different shapes (as per needs) with very little power and ensures a satisfactory finish. So, you don’t require much tooling and effort while shaping 6061.

Note: There are two essential factors to consider when calculating the mechanical strength of 6061: Ultimate strength and Yield strength. Ultimate strength is the maximum stress that the alloy can withstand without or before permanent deformation. Whereas the Yield strength is

amount of stress (maximum) required to deform the alloy elastically by compression or twisting.

6061 Top Uses

You will see the main usage of this 6061 alloy as a material for manufacturing various automotive parts. People also use it to construct bicycle frames, yachts, scuba tanks, couplings, motorcycles, valves, and electric fittings. Besides, many also prefer this alloy to make inside foil wrappers of food containers and for manufacturing aluminum cans. Nowadays, Aluminum-magnesium-silicon alloys are widely in use for creating wide-span roof frames for bridge decks and sitting arenas. Other than the above uses, 6061 serves as the construction material for:

- Marine frames

- Welded assemblies

- Heat Exchangers

- Electronic parts

- Chemical equipment

- Furniture

- Heat Sinks

- Fasteners

Where Can You Find High-Quality Aluminium Alloy 6061?

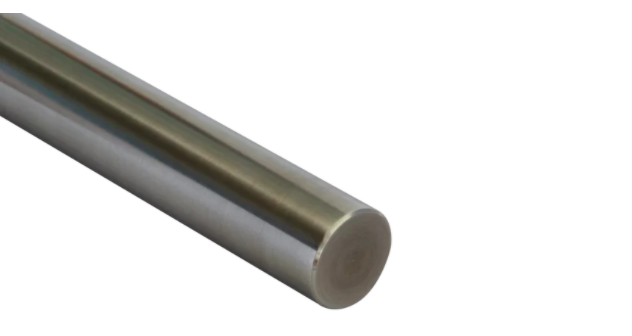

Kormax Designs manufactures top-notch 6061 aluminum alloy in several custom shapes to meet the needs of a wide range of applications. From hollow shapes and bar products to rods and structural tubes – they have everything that you can need. Also, they can help you to customize the shape of alloys as per your requirements.

So, that’s all for now. We will be back soon with more information!