Quick Rundown of Engineered to Perform Boiler Gaskets

Well, boiler gaskets have been an important part of millions of commercial and residential buildings. Many premium brands have pioneered manufacturing both gas-fired and oil-fired boilers. Generally, if you are planning to invest in a few, your choice will be based on several factors such as gas supply, fuel supply, and the space available for placing the boiler with a tank. What is more, with a comparison of efficiency ratings, you can check it easily online with the availability of gaskets and other boiler parts.

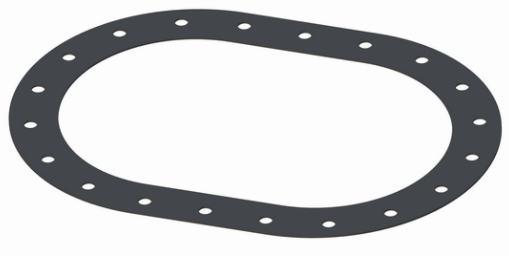

Normally, like every other steam and hot water system, your boiler also uses gaskets manufactured by premium brands like Oswald Supply. If you look at the handholes and manholes providing access, you will certainly find gaskets around them. Gaskets that are engineered to perform prevent any leakages in exhaust ducting and pipe joints.

There can be situations when you might find that the boiler has stopped working; well, that is the time when you need to be prepared for the serious consequences. Water, steam, or exhaust gas leakages add to the operating costs and turn out to be extremely dangerous while reducing the efficiency levels.

This is the only reason you should check for the specifications and manufacturing of the gaskets while purchasing. If possible, then make sure to check the condition of the manhole gaskets regularly. And as expert engineers recommend, check whether they need replacement after a year or two.

Furthermore, boilers have a heat exchanger, or we can call a burner, the heating element. Technically, the chemical treatment of water around it prevents corrosion. This is the place where the heating burner comes into action. With a steam-producing boiler, the temperature and pressure can exceed 380 F and 180 PSI.

MAINTENANCE OF THE GASKET BOILERS

If you ever decide to turn off the boiler, then you also need to keep in mind that it can be expensive and disruptive at the same time. Normally, expert engineers recommend this to only practice at the time of the annual maintenance. Or else, we can say that an annual inspection is a great way to do this and enhance the gasket boiler’s performance. However, do not forget to clean your boiler regularly.

The grit and the smoke in different areas can extremely impact the lifespan and efficiency of the boiler. Make sure to check for it periodically and remove it so that all the components keep functioning properly. Yes! Do not overlook the cleaning and inspection of handholes and manholes. In case you see any signs of leakages and corrosion, get a new one. With this, assure not to reuse the gaskets as it brings the boiler to a halt.

So that was all a beginner needs to know about the gasket boilers available in the market. Make sure to consider the material and features of the product before making any final purchase.